The acrylic plastic rod is 200mm long – The acrylic plastic rod, measuring 200mm in length, presents a versatile material with a unique combination of physical and chemical properties. This article delves into the intricate details of this material, exploring its composition, molecular structure, and the applications it serves across diverse industries.

The acrylic plastic rod, with its exceptional strength, flexibility, and clarity, finds applications in various fields, including optics, construction, and manufacturing. Its adaptability stems from its ease of shaping, cutting, and polishing, making it a preferred choice for customized designs.

1. Physical Properties of the Acrylic Plastic Rod

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic material renowned for its exceptional optical clarity, strength, and durability. It is composed of methyl methacrylate monomer units, which are polymerized to form a long-chain structure.

The molecular structure of acrylic plastic consists of a repeating sequence of carbon, hydrogen, and oxygen atoms arranged in a linear chain. The strong covalent bonds between these atoms contribute to the material’s rigidity and resistance to deformation.

Acrylic plastic rods exhibit several notable physical characteristics. They have a density of approximately 1.19 g/cm³, making them relatively lightweight. Despite their low density, acrylic rods possess remarkable strength and stiffness, with a tensile strength of around 70 MPa and a modulus of elasticity of approximately 3.2 GPa.

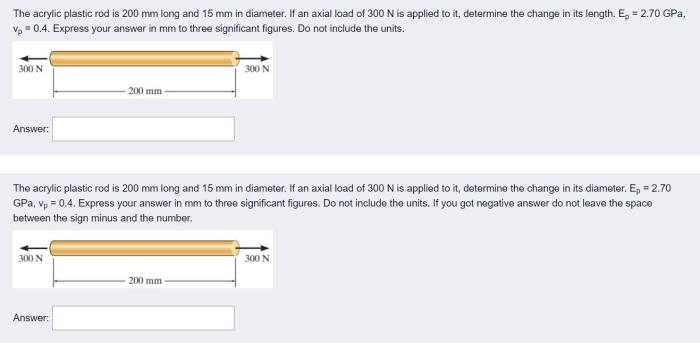

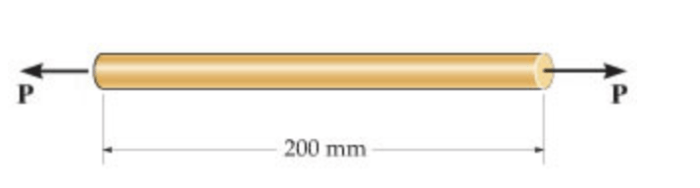

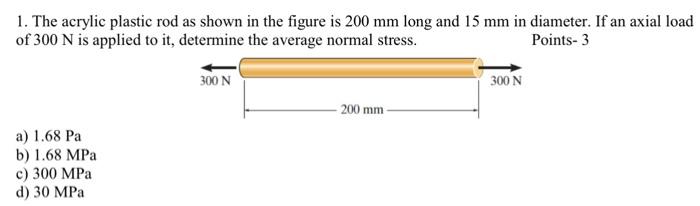

2. Dimensions and Shape of the Rod

The acrylic plastic rod under consideration has a length of 200mm. It is cylindrical in shape, with a uniform diameter throughout its length.

3. Applications of the Acrylic Plastic Rod

Acrylic plastic rods find applications in a wide range of industries due to their unique combination of properties. Their optical clarity and resistance to yellowing make them ideal for use in lighting fixtures, lenses, and displays.

The strength and durability of acrylic plastic rods make them suitable for structural applications, such as in machine guards, display stands, and architectural elements. Their resistance to chemicals and solvents allows them to be used in laboratory equipment and medical devices.

Examples of products and projects that utilize acrylic plastic rods include:

- Acrylic display cases for museum exhibits

- Lenses for camera equipment

- Transparent panels for architectural glazing

- Medical devices such as test tubes and petri dishes

4. Manufacturing and Processing of the Rod: The Acrylic Plastic Rod Is 200mm Long

Acrylic plastic rods are typically manufactured through a process called extrusion. In this process, molten acrylic plastic is forced through a die to create a continuous rod with the desired shape and dimensions.

After extrusion, the rods can be further processed to achieve specific properties or shapes. They can be cut to length, polished to a smooth finish, or drilled and tapped to accommodate fasteners.

Special treatments, such as heat treatment or chemical etching, can also be applied to enhance the rod’s properties or create decorative effects.

Clarifying Questions

What are the key physical properties of acrylic plastic?

Acrylic plastic is known for its exceptional strength, rigidity, and resistance to impact and chemicals. It possesses a high light transmittance, making it optically clear, and exhibits good electrical insulation properties.

What are the common applications of acrylic plastic rods?

Acrylic plastic rods find applications in a variety of industries, including optics, lighting, construction, and manufacturing. They are used in lenses, light guides, display cases, furniture, and even medical devices.

How is the acrylic plastic rod manufactured?

The acrylic plastic rod is typically manufactured through a process called extrusion, where molten acrylic plastic is forced through a die to create a continuous rod shape. The rod can then be cut to desired lengths and polished for a smooth finish.